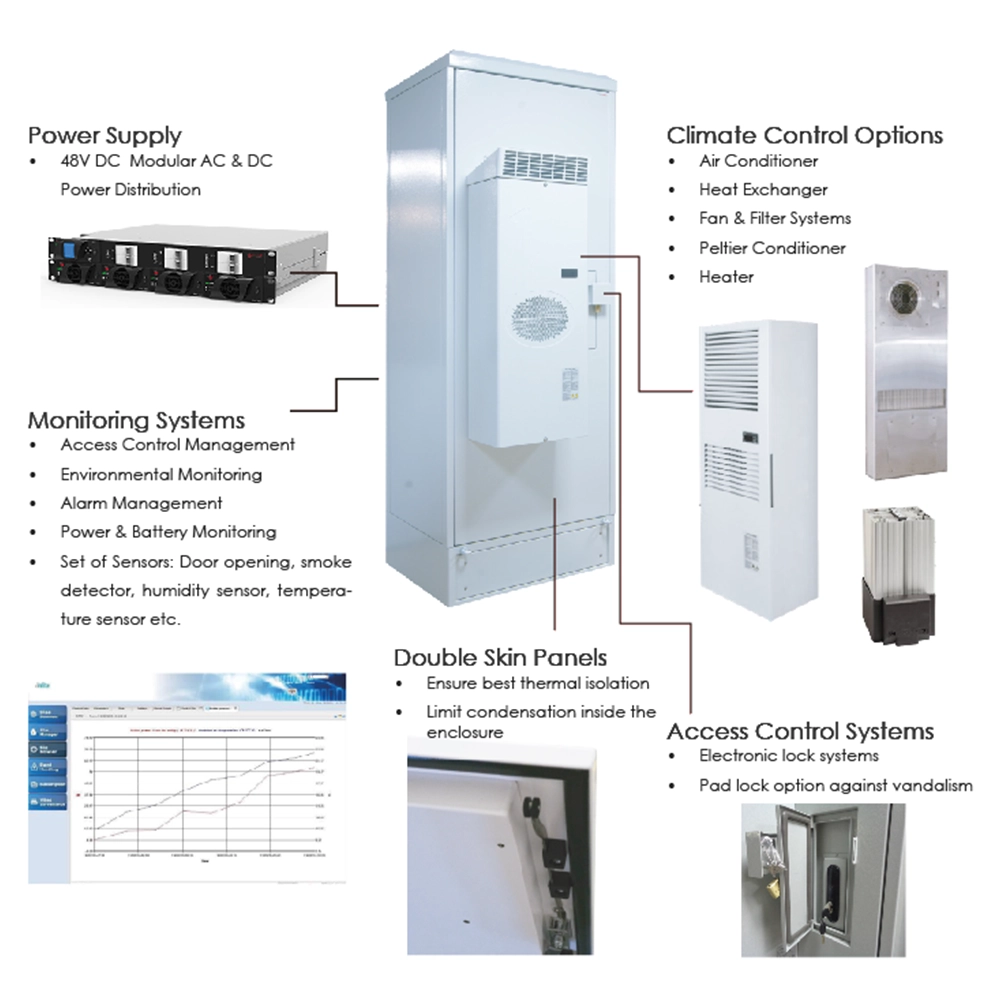

Description

Explosion proof cabinets prevent explosions or infernos from spreading to the surroundings of an internally exploding device. The net outcome is a safer work environment for personnel in industrial facilities that are prone to explosion. The safeguards also help to prevent damage to property, thus shielding investors or manufacturing facilities owners against potentially heavy financial losses.

Sturdy materials, such as cast metal are used to build the cabinet’s outer shell. Such a heavy-duty construction contains any excess pressure that an internal eruption creates, preventing propagation into the enclosure’s immediate environment.

Ingress protection involves sealing electrical enclosures to prevent the entrance of foreign bodies, such as vapor and flammable gases.

Ex-Proof and Military Standards

– ATEX 100a-94/9/EC “Appareils destinés à être utilisés en ATmosphères EXplosives” (French for Equipment intended for use in EXplosive ATmospheres).”

– MIL-STD-810G “Department of Defence Test Method Standard for Environmental Engineering Considerations and Laboratory Tests”, 31/10/2008.

– MIL-STD-461F “Department of Defence Interface Standard; Requirements for the Control of Electromagnetic Interference Characteristics of Subsystems and Equipment”,

– EN61000-4-2 “ Electromagnetic Compatibility (EMC) Testing and Measurement Techniques. Electrostatic Discharge Immunity Test. Basic EMC Publication”

Application Areas

– Mining Industry

– Oil refineries

– LPG & Gas terminals

– Chemical plants

– Military areas

– Fuel servicing sites

– Feed mills and fertilizer plants

– Plastic/fireworks factories