Description

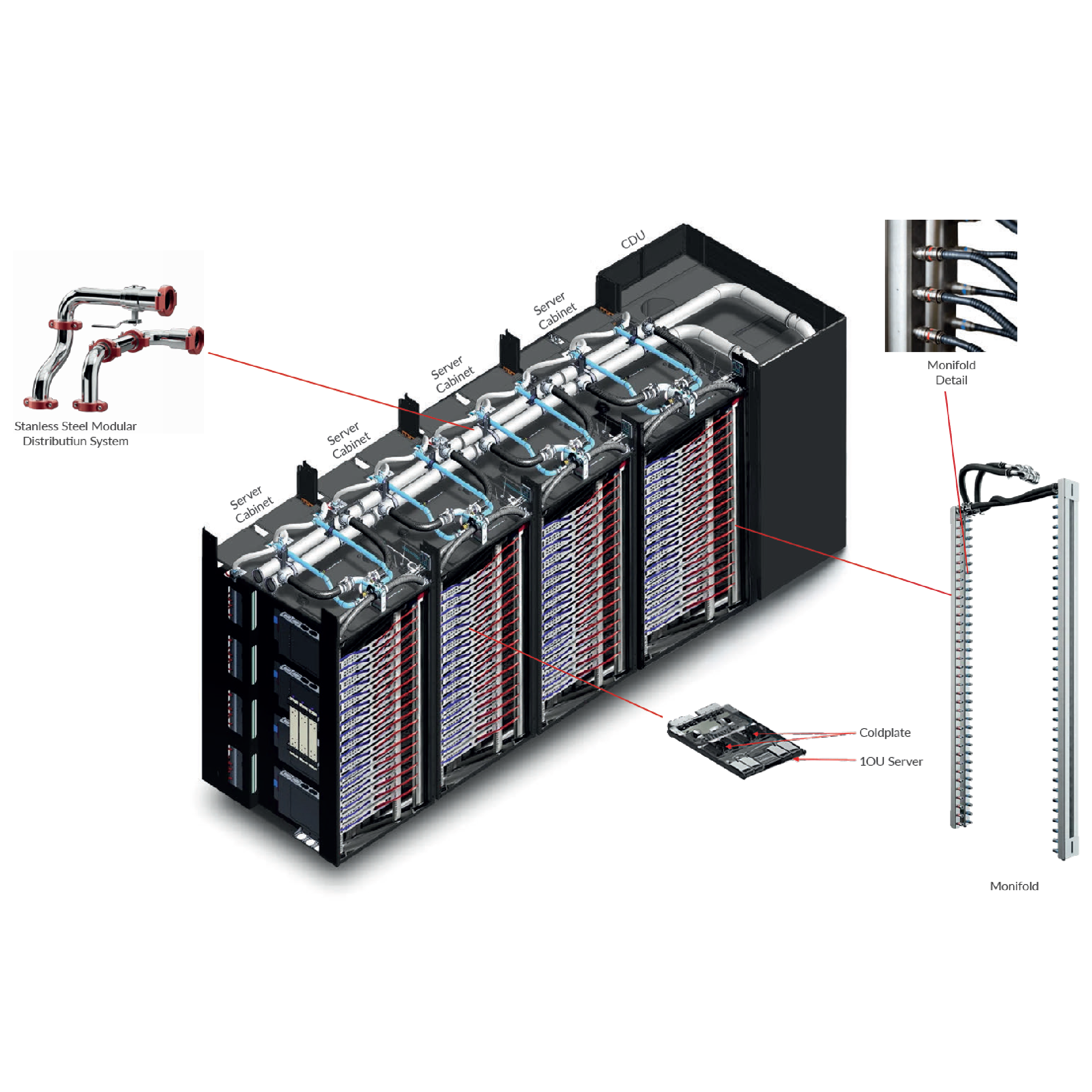

Advantages of Direct-to-Chip Liquid Cooling:

Lower Power Usage Effectiveness (PUE)

– Direct-to-chip liquid systems can achieve PUE values closer to 1.03-1.05 , compared to 1.5+ for traditional air-cooled systems.

– Reduced reliance on fans and air handling units cuts down cooling power consumption.

Superior Thermal Performance

– High heat removal efficiency: Liquids have a much higher thermal conductivity than air (about 1,000x), enabling more efficient heat transfer.

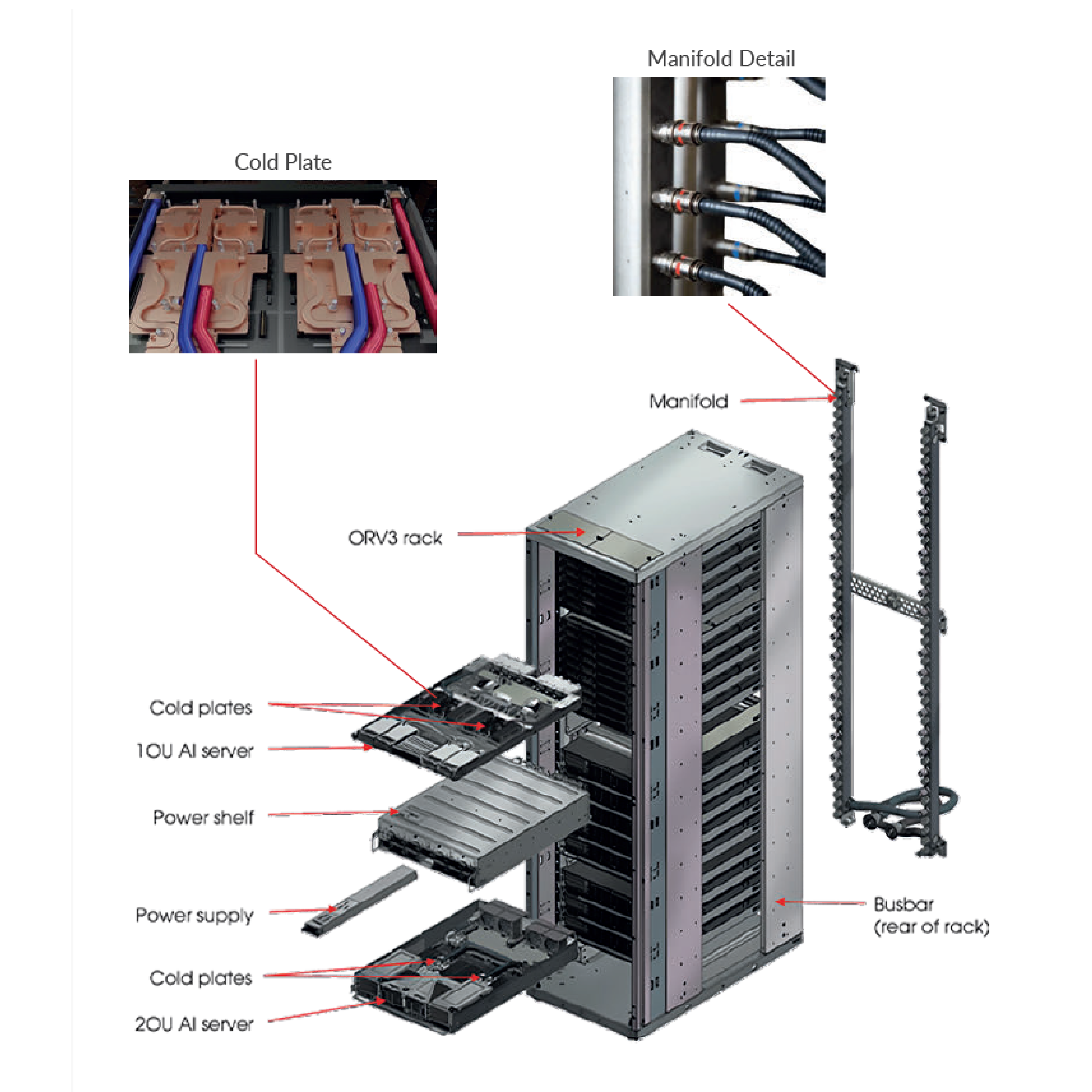

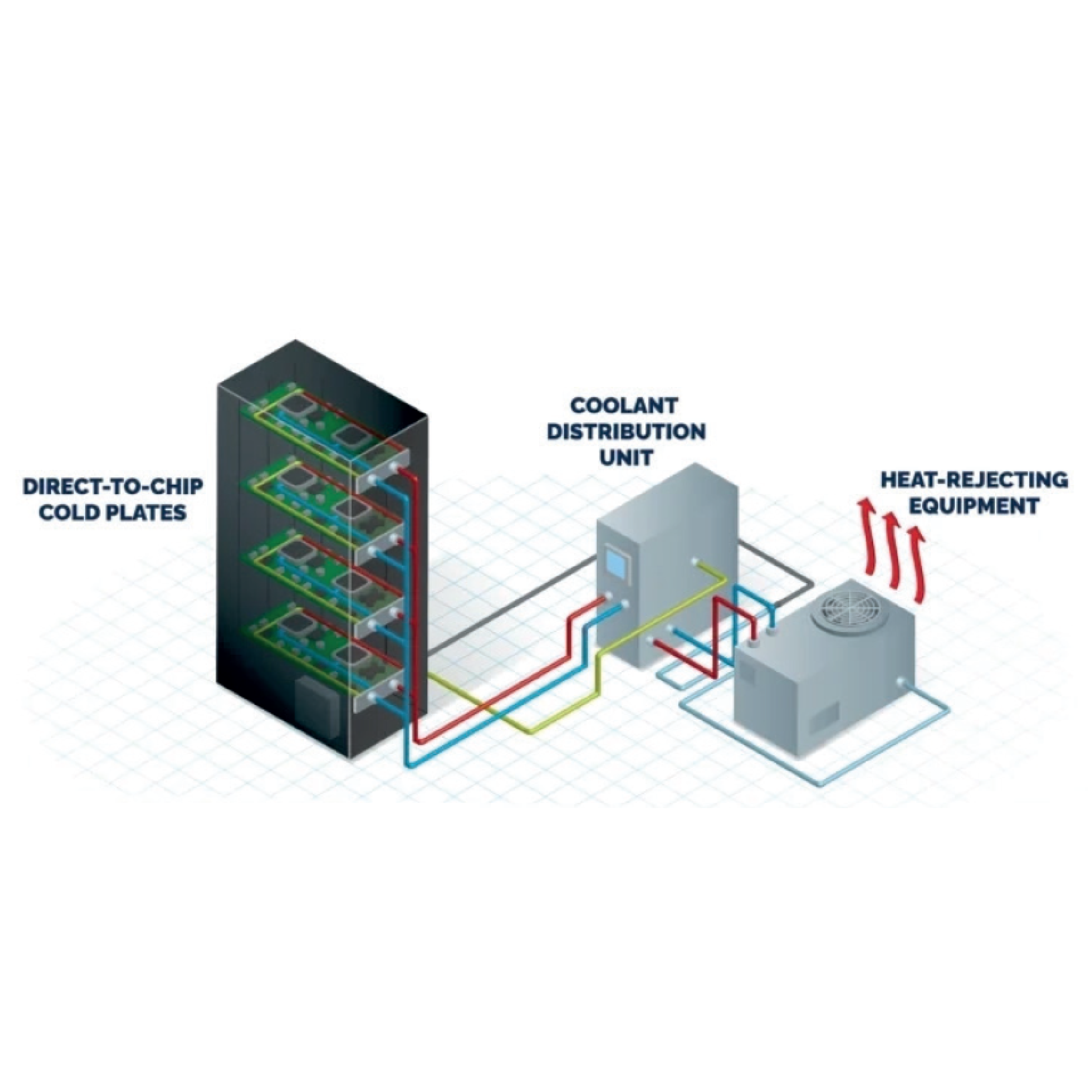

– Targets hotspots directly: Coolant flows through cold plates mounted on CPUs, GPUs, and memory chips, extracting heat at the source.

Support for Higher Density Deployments

– Allows servers to run at higher power densities (Up to 110kW/ rack), which would be difficult or impossible to cool with air.

– Facilitates more compact data center layouts.

Quiet Operation

– Fewer and smaller fans are required, resulting in quieter data center environments.

Reduced Data Center Footprint

– Less space needed for CRAC units, ducting, and raised floors.

– Enables more efficient use of space within existing facilities.

Improved Component Reliability

– More consistent and lower operating temperatures can increase the lifespan and reliability of processors and other critical components.

Waste Heat Reuse Potential

– Since the coolant can leave the cold plate at higher temperatures (e.g., 50–65°C), it opens opportunities for heat reuse (e.g., heating buildings or water).

Environmental Friendly

– Reduces energy consumption and carbon footprint.

– Can integrate with free cooling (e.g., using outside air or water towers to cool the liquid).