Industry 4.0 and Automation: Digital Transformation in Manufacturing

With the advancement of industrial revolutions, transformative innovations have reshaped production and industrial processes. Industry 4.0 represents the latest phase in this evolution, driving the digital transformation of manufacturing through technologies such as automation, artificial intelligence, and the Internet of Things (IoT). But what exactly is Industry 4.0, and how does it integrate with automation?

What is Industry 4.0?

Industry 4.0 refers to the integration of digital technologies into production processes and the management of these processes through intelligent systems. This new industrial revolution aims to create more efficient, flexible, and intelligent production environments by merging physical production systems with digital technologies. Industry 4.0 optimizes everything from production to supply chain, providing businesses with significant competitive advantages.

The basic components of Industry 4.0 include IoT, big data analytics, cloud computing, cyber-physical systems, artificial intelligence, and robotic automation. These technologies enable faster and more accurate decisions by digitalizing production processes.

The Role of Automation

Automation is one of the core pillars of Industry 4.0. By using automation in production, businesses can reduce human intervention, streamline processes, and achieve faster, more efficient, and error-free operations. Automation not only allows machines to handle repetitive tasks but also optimizes processes through intelligent systems.

With Industry 4.0, traditional automation solutions become smarter. Automation systems, powered by sensors, data collection systems, and IoT technologies, can continuously analyze real-time data to improve themselves. This leads to higher efficiency and quality control in production processes.

Advantages of Industry 4.0 and Automation

Increased Efficiency: Automation optimizes repetitive and manual work, enabling faster and error-free production. By leveraging machine learning and artificial intelligence, automation systems can continuously refine processes, offering businesses greater efficiency.

Flexibility and Customization: With Industry 4.0, automation systems become more adaptable. Production lines can be rapidly adjusted to customer demands and market shifts. Custom production solutions allow businesses to offer more personalized products to their clients.

Reduced Costs: Automation and digitalization reduce labor costs and minimize error rates. Furthermore, energy efficiency is improved, helping lower operating costs. Automation also minimizes downtime and maintenance needs.

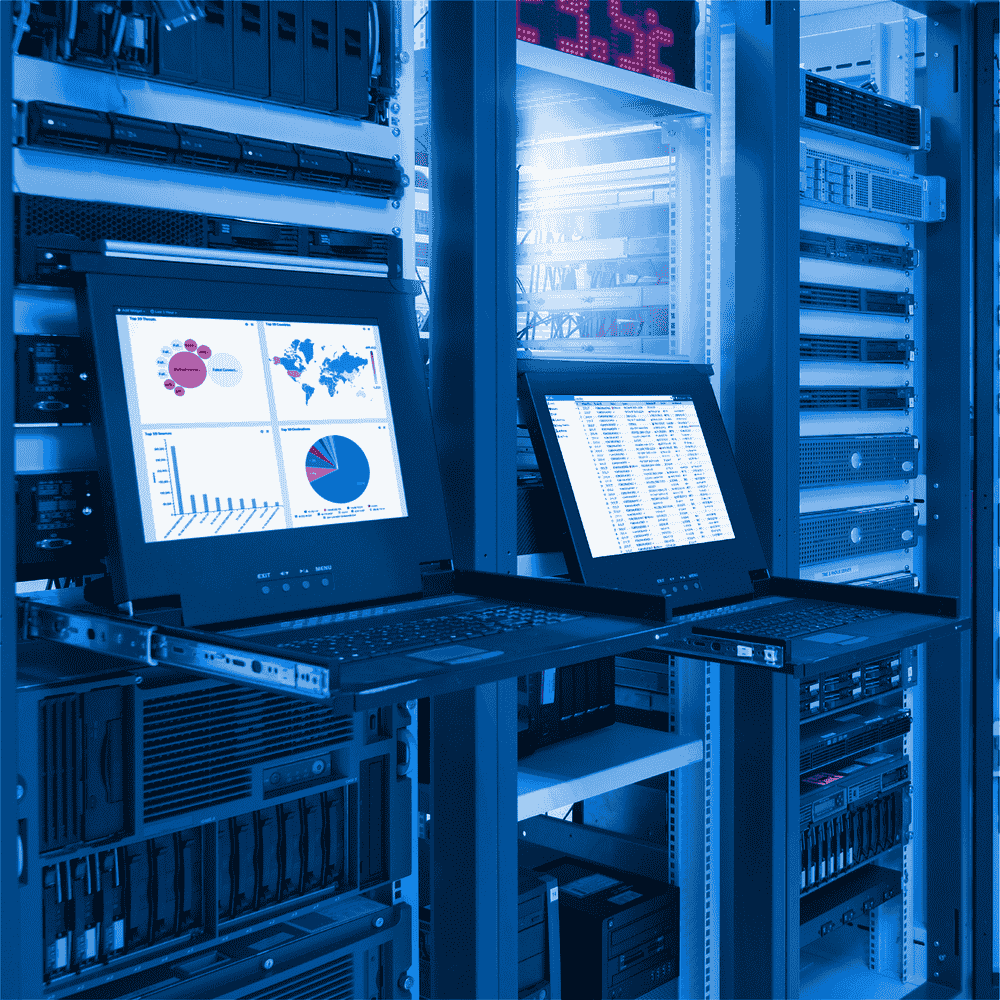

Quality Control: With sensors and data analytics, automation systems optimize quality control. The early detection of errors and automatic corrections ensure better product quality.

Real-Time Data Analysis: Industry 4.0’s digital transformation enhances the use of big data analytics in production. Automation systems analyze collected data and allow for immediate optimization of production processes.

Work Safety: Automation reduces the need for human labor in dangerous tasks, improving workplace safety. This is especially beneficial in industries such as heavy manufacturing and production.

Areas of Use of Industry 4.0 and Automation

Production Facilities: Industry 4.0 and automation technologies improve efficiency in production facilities by enabling machine communication and process management. Smart factories optimize operations and reduce costs.

Supply Chain Management: Automation systems are integral to supply chain management. By using IoT sensors and big data analytics, every stage of the supply chain can be monitored and optimized, improving inventory management and logistics.

Agriculture and Food Production: Industry 4.0 revolutionizes agriculture, using automation and IoT devices to improve efficiency and resource management in agricultural processes.

Automotive Industry: The automotive sector uses Industry 4.0 and automation technologies to create flexible production lines and custom processes, while enhancing quality control with smart robots and sensors.

The Transition Process to Industry 4.0

The transition to Industry 4.0 and automation requires careful planning. Businesses need to take several crucial steps to succeed in this digital transformation process:

Digital Transformation Strategy: Create a strategy by assessing the current state of your business and setting future goals. Decide which processes will be automated and which technologies will be implemented.

Education and HR Management: Automation systems require employees to have digital skills. Training your workforce on Industry 4.0 technologies will help facilitate the transition and improve your team’s adaptability.

Data Analytics and IoT: Big data analytics and IoT sensors are essential elements of Industry 4.0. Investing in these technologies will boost the efficiency of your production processes.

Collaboration and Integration: Successful Industry 4.0 solutions require integration across different departments and processes. Ensuring seamless collaboration will amplify the effectiveness of automation and digital transformation.

Conclusion

Industry 4.0 and automation are pivotal for optimizing all business processes, from production to the supply chain. These technologies offer numerous benefits, including increased efficiency, cost savings, flexibility, and enhanced quality control. Smart production and automation solutions help businesses remain competitive while fostering more sustainable and efficient environments.

If you would like more information about transitioning to Industry 4.0 and automation solutions, contact our expert team. We can guide you in preparing your business for the future with the most suitable digital transformation solutions.